Task 3 Plan

Due to the seismically induced deformation of tall CLT buildings, resilience-critical components are expected to be mostly drift sensitive. These components include non-load-bearing walls (e.g. wood or light gage steel stud walls with gypsum board), exterior curtain wall systems, vertical piping systems, and elevators and egress systems.

The goals of this task are three-fold: 1) identify suitable details for connecting the nonstructural systems to the CLT structural system, 2) identify the contribution of nonstructural systems to the stiffness and strength of the structural system (with Task 2), and 3) develop or modify existing fragility models that connect functionality to seismic demands and resilience performance targets.

Progress

Nonstructural Team Announces Funding from U.S. Forest Service

We are happy to announce receipt of a U.S. Forest Service Wood Innovation Grant to support a payload effort with non-structural system focus. The project entitled “Advancing Tall Mass Timber Buildings through Seismic Resilience Testing”, is led by Prof. Keri Ryan of UNR and Prof. Tara Hutchinson of UCSD, with Prof. Shiling Pei as a senior collaborator. In this project, we aim to identify the most vulnerable NCSs, and develop methods to protect them from the specific demands imposed by the rocking timber wall systems. We will work with industry to design, install and monitor the seismic performance of representative drift and acceleration sensitive NCSs in the 10-story building. We will use this data to quantify the relation between ground shaking level, structural responses and performance of the NCS, and overall quantification of building resilience. Finally, we will disseminate research findings widely to the timber design and NCS expert communities. The project provides resources for personnel, travel, and some testing related expenses.

This project follows US Department of Agriculture civil rights regulation and policies; please see information here.

Seeking Industry Collaborators to Contribute to the Nonstructural Component Objectives for mid-2021 10-story Test

We are actively seeking industry collaborators to contribute to the nonstructural component objectives for the mid-2021 10-story test. We are asking for material donations with delivery, support for fabrication and disposal, in-kind engineering and design support, and small cash contributions as needed to support the testing. We are open to testing a variety of nonstructural components, but our highest priorities are nonstructural partition walls, lightweight building skins, and stairs with fire protection details.

Our vision for including nonstructural components in the test program is described in the following paper, presented at 5th Residential Building Design and Construction Conference (RBDCC) at Penn State University, March 5, 2020.

A webinar delivered to the Fenestration and Glazing Industry Alliance (FGIA) on January 21, 2020, provided useful information for potential collaborators. The presentation slides are archived here.

Nonstructural Partition Wall Testing at Lehigh University

Two phases of testing on nonstructural partition walls were completed at Lehigh University in September of 2019. This test program utilized the test setup for bidirectional load testing of coupled CLT rocking walls with gravity framing. The partition walls were installed between the floor diaphragms. We are especially grateful to the support provided by our industry collaborators, led by Eastern Exterior Wall Systems and Duggan and Marcon, who coordinated the donation of materials and fabrication of the test walls.

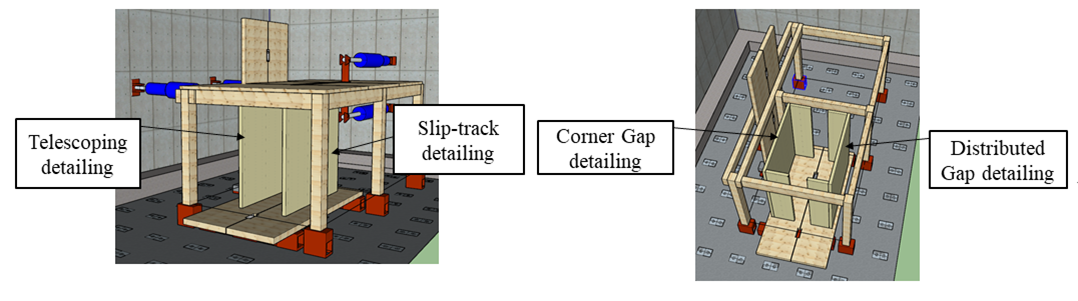

The partition wall testing has focused on alternative detailing that can reduce drift-induced damage in nonstructural partition walls. The relevance of this research is that in most loss estimation studies, damage in low level earthquakes is dominated by damage to partition walls, and the damage tends to initiate at relatively low levels of shaking (around 0.4% interstory drift). In the first test phase, we compared two straight walls: one with a double top track detail (called telescoping slip track) and the other with traditional slip track detailing. One drawback of the slip track detailing is that the studs can pop out from the top track, or bind up upon load reversal. The telescoping detail was shown to hold the wall system together under large drifts, compared to the slip track detail that produced some damage at the wall ends. Thus, we recommend the telescoping detail as an option to improve seismic resiliency.

The second phase of testing focused on a more problematic issue, which is that the partition walls with slip track detailing tend to get damaged at intersecting walls or return walls. The reason is that in-plane walls slip with respect to the floor above, while out-of-plane walls move with the floor above. Thus, the moving out-of-plane walls and stationary in-plane wall inevitably collide. We tested two different details intended to alleviate this intersection damage. The first was to detail the corner as a gap that allows the walls to penetrate into the corner region. This detail performed well with only damage to the sacrificial corner beads, up to drifts of about 3%. The second detail used periodic 0.5” expansion gaps to absorb some of the relative drift between intersection walls. The gaps directly adjacent to intersecting walls were effective in absorbing some of the relative drift, and delayed the onset of damage to almost 1% drift. However, the expansion gaps tended to open up when the out-of-plane wall and in-plane wall moved in the opposite direction. After multiple cycles, these gaps permanently pulled apart, leaving the partition wall separated into isolated sections. After becoming isolated from the rest of the wall segments, the corner segments showed a susceptibility to local collapse. We would like to iterate on this detail, but face the possibility that its drawbacks will ultimately outweigh its benefits.

Preliminary Test Reports

Phase I test report Here

Phase II test report Here

Time Lapse Videos

Phase I Slip track vs Telescope

Phase II Corner Gap

Phase II Distributed gap

Partnership with Construction Specialties to Investigate Seismic Performance of Stairs and Fire Protection Walls

We are currently collaborating with Construction Specialties to incorporate stairs and surrounding fire protection walls into the 10-story building test. Construction Specialties manufacturers and sells a variety of architectural building products, including expansion joint covers, wall coverings and fire barriers. Construction Specialties Drift Ready stair system uses a flexible connection to allow relatively free movement between the stair tread assembly and landing to absorb interstory drift.

The complexities of the interactions between the structural system, stair unit, and surrounding fire protection have not yet been explored in a realistic building environment. For this project, we are exploring a variety of solutions including:

-- A self-supporting, modular self-contained stair core unit with integrated fire protection walls.

-- Stairs and fire protection walls designed as separate units.

-- A hybrid solution that uses Construction Specialties fire barrier expansion joints.

With 10-stories to work with, a variety of details and detailing combinations can be explore!